|

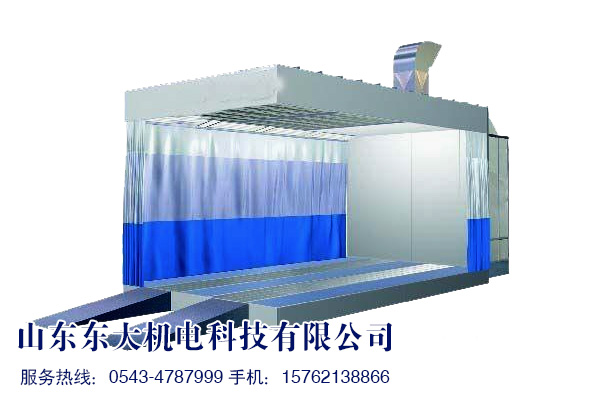

Grind room

Hits:1108

Time:2018-05-14 16:03:40

|

Description

Dd-100 grinding room

Outer diameter 7000× 3700× 3250 inner diameter 6900× 3600× 2800 total power

The of the body system;

1. The top static pressure chamber is formed by cold bending steel sheet, and the roof is galvanized and bent to assemble.

2. Front and side of the equipment: adopt PVC soft curtain to slide on the aluminum alloy guide rail.

3, back wall: the use of 50mm thick EPS insulation board.

4. Platform: adopt integral type antirust exhaust platform, composed of tread panels and high-strength grille to form a walking platform.

The overall structure is light, novel and beautiful in appearance, with good strength, stiffness, stability and impact resistance.

Air supply and exhaust system

1, the YDW series double inlet centrifugal fan is made by galvanized sheet molding, with large air volume, low noise and good temperature resistance. It is produced by special fan plant.

2, fan cabinet: use profile production framework, steel plate spray cabinet assembly, the structure is stable, reliable, beautiful, easy to maintain.

Air purification system

Using high quality filter cotton, the filter cotton has a multi-layer structure, set at the bottom of the static pressure chamber, supported by the top net, the top net is C steel structure, no corrosion, easy to replace the top cotton, and can effectively capture the dust particles with diameter larger than 5μ m.

Environmental protection system

The first ground cotton is placed under the grille of the return air channel to capture large dust particles. Second glass fiber cotton is located in the exhaust cabinet to capture the remaining dust.

Lighting system

A lighting unit is installed on the top side of the housing body, and 24 shadowless lighting tubes are arranged, so that the light inside the house is soft, and the illumination is uniform and bright. The ballast is a special ballast with stable performance and long service life.

Electronic control system

The selected high-quality electronic components are assembled and the operator can complete the whole operation process at one time. The main circuit is equipped with multiple protection: overcurrent, overload, short circuit and lack of equal protection. Equipped with grinding switch, lighting switch, emergency stop switch, fault alarm, etc.

.DD-200 type grinding room of conventional standard type grinding house

Outer diameter 7000× 3700× 3250 inner diameter 6900× 3600× 2500 total power 7.0KW

The of the body system;

1. The top static pressure chamber is formed by cold bending steel sheet, and the roof is galvanized and bent to assemble.

2. Front end of the equipment: use PVC soft curtain to slide on the aluminum alloy guide.

3, the sides of the equipment and the rear side wall: adopt 50mm thick EPS insulation board.

4. Platform: adopt integral type antirust exhaust platform, composed of tread panels and high-strength grille to form a walking platform.

The overall structure is light, novel and beautiful in appearance, with good strength, stiffness, stability and impact resistance.

Air supply and exhaust system

1, the YDW series double inlet centrifugal fan is made by galvanized sheet molding, with large air volume, low noise and good temperature resistance. It is produced by special fan plant.

2, fan cabinet: use profile production framework, steel plate spray cabinet assembly, the structure is stable, reliable, beautiful, easy to maintain.

Air purification system

High quality filter cotton produced in Italy, the filter cotton has a multi-layer structure, set at the bottom of the static pressure chamber, with top net support, the top net is C steel structure, no corrosion, easy to replace the top cotton, can effectively capture the diameter of the dust particles larger than 5μ m.

Environmental protection system

The first ground cotton is placed under the grille of the return air channel to capture large dust particles. Second glass fiber cotton is located in the exhaust cabinet to capture the remaining dust.

Lighting system

A lighting unit is installed on the top side of the housing body, and 24 shadowless lighting tubes are arranged, so that the light inside the house is soft, and the illumination is uniform and bright. Ballast is a special ballast with stable performance and long service life.

Electronic control system

The selected high-quality electronic components are assembled and the operator can complete the whole operation process at one time. The main circuit is equipped with multiple protection: overcurrent, overload, short circuit and lack of equal protection. Equipped with grinding switch, lighting switch, emergency stop switch, fault alarm, etc.

Car Grinding Room

Car Grinding Room

鲁公网安备 37162602000267号

鲁公网安备 37162602000267号